CAPABILITY

Concept design

Based on our long experience in designing a wide range of blow molding spoilers, MOYA provide the best design to meet customer needs. MOYA provide the best design of products that meets Aero-dynamics elements, various regulations while enhancing the styling of the vehicle.

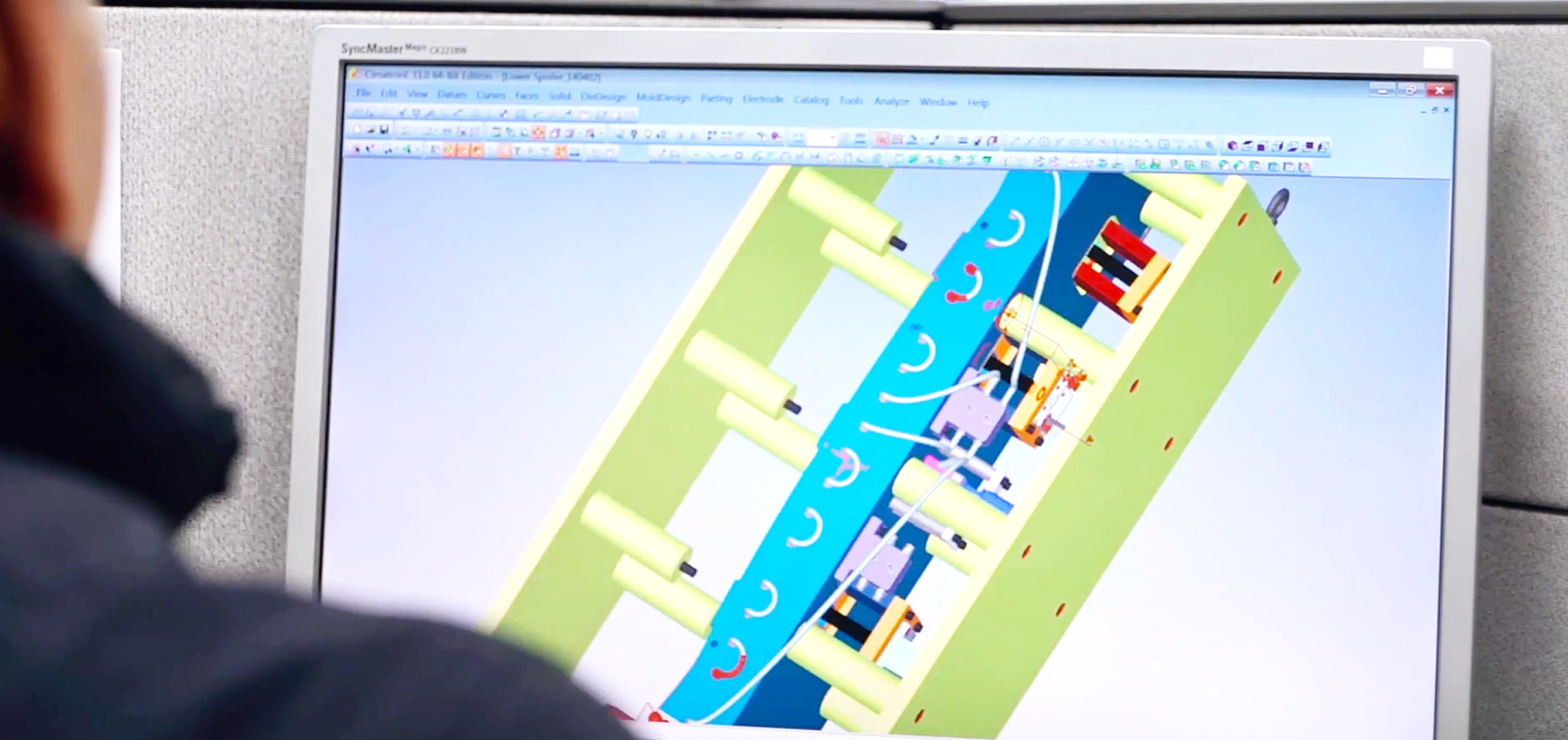

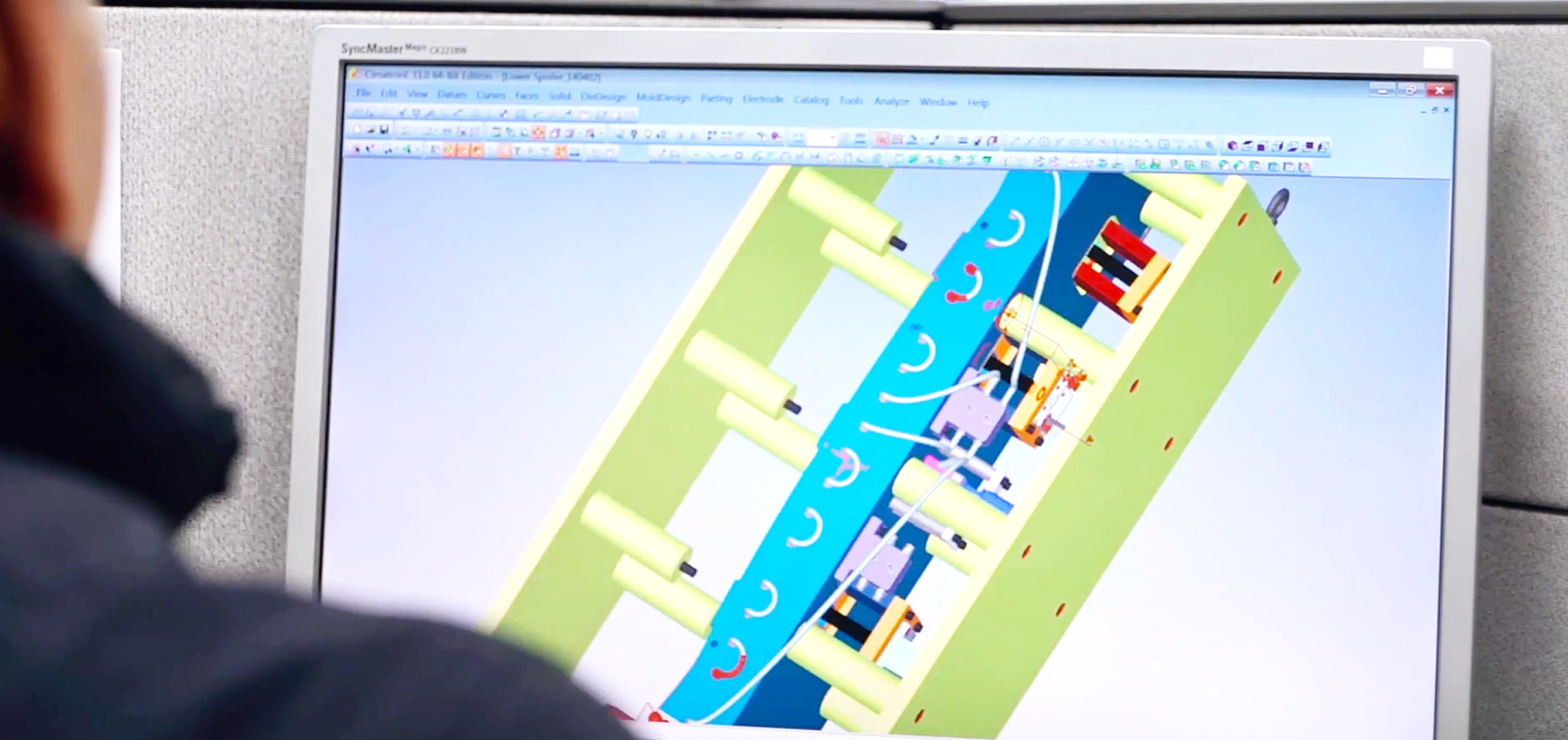

Engineering Design

Based on concept design, MOYA has more than 25 years of experience in engineering design that can be applied to blow molding by collaboration of design engineer, Tool engineer, molding engineer and production engineer. Starting from mold design, Product design, part design, Check fixture design and applicability of production facilities are reviewed, MOYA do engineering design the product to reflect concept design sufficiently.

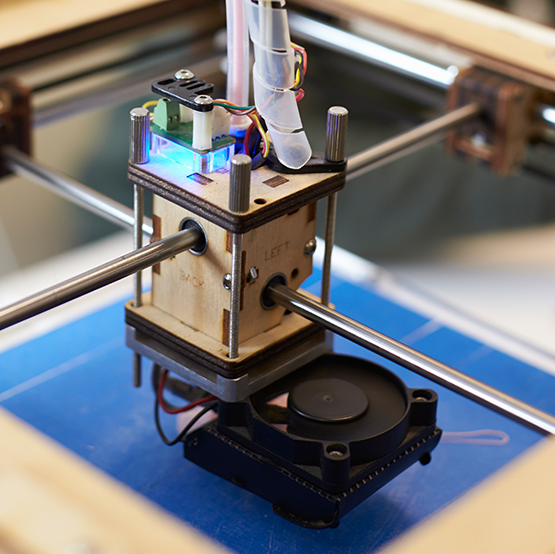

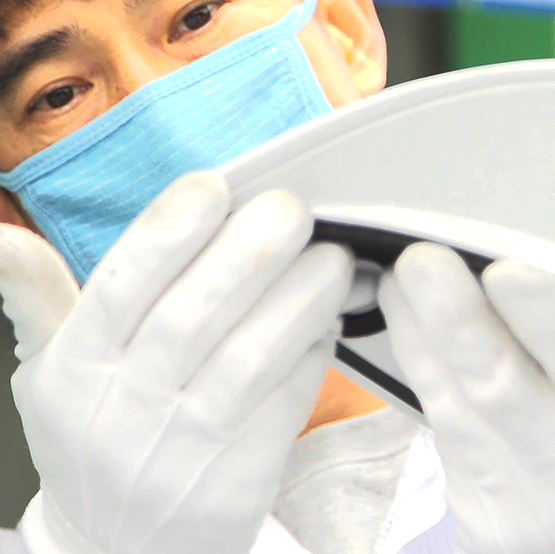

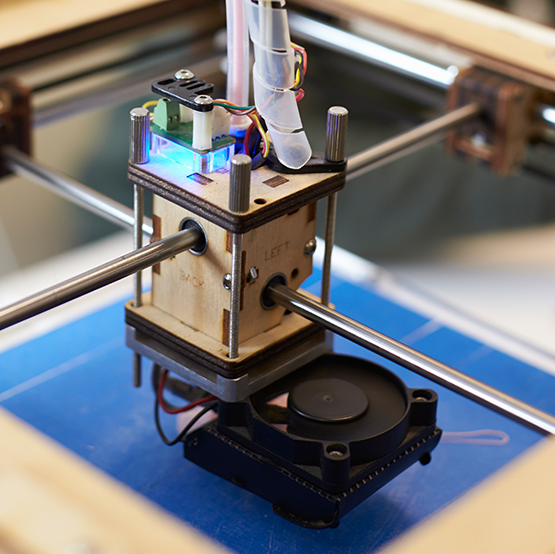

Prototyping

Based on the concept design, we build prototype samples by checking our engineering designs before going into tooling and production. By checking the samples in real size before entering the mold, We can verify the match with with the vehicle, assembly problems, compatibility with various processes, packaging and more issues before mass production.

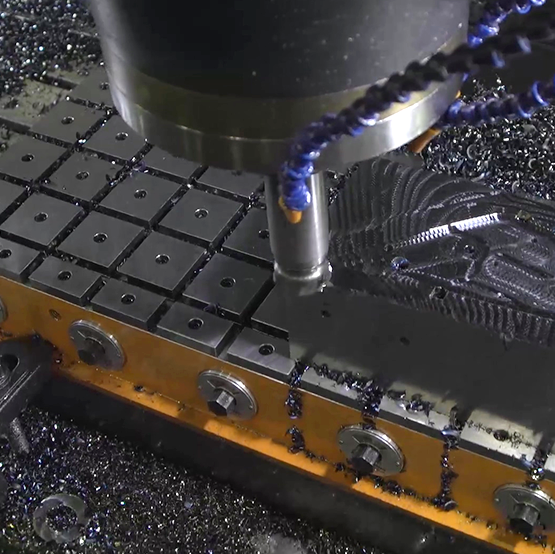

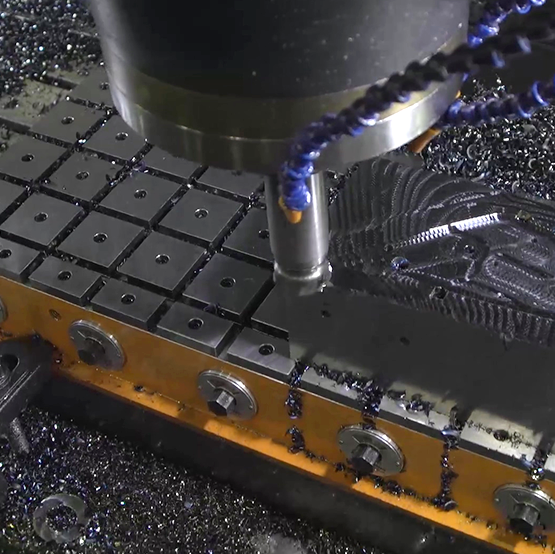

Tool Design

Based on Moya’s 30 years of experience in blow molding engineers, MOYA can make molds optimized for blow molding. A mold is built to produce the optimal blow molding product based on the experience of develop blow molding spoiler for a long time and patents related to blow molding process.

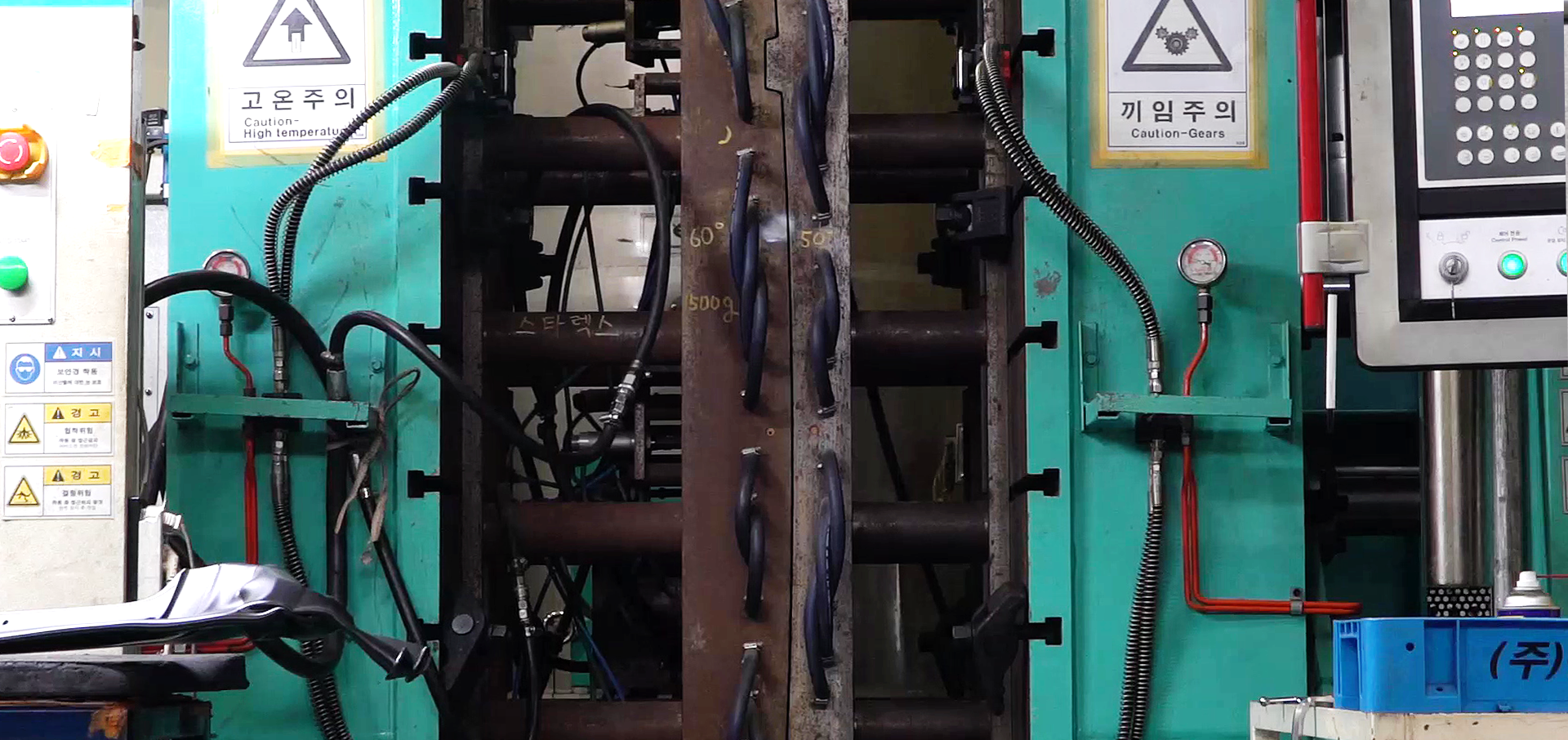

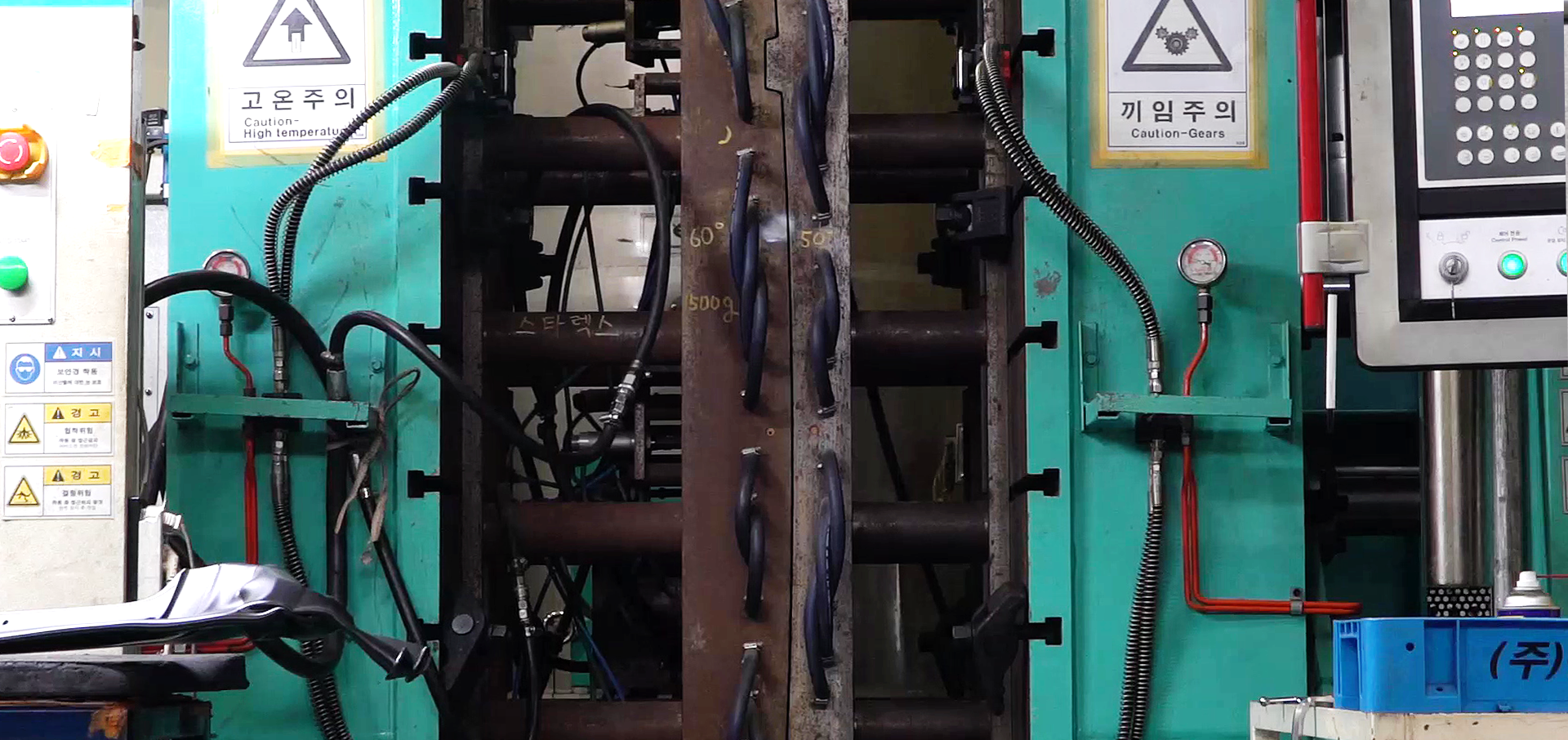

Blow Molding

Blow molding is a technique that produces products with hollow structures. It is a technique to mold a product by blowing half-melted resin, blowing air into a mold. Blow molding can produce a spoiler through a single process. Blow molding has many advantages in strength, design and many parts. By injection molding, need several process to make hollow type of spoiler. Moya can supply World best blow molding products with 25years experience.

Sanding

It is the process of sanding the surface of the blow molded product and making it the optimal condition for painting. MOYA have a long experience and know-how to treat the surface of the product to the best product.

Painting

Moya operates two independent conveyor painting lines, it is the top loading method and the floor loading method. Both painting lines are operated with top OEM quality painting level optimized for each product shape and painting method. With over 20 years of experience, our highly trained engineers are producing the best results with our craftsmanship.

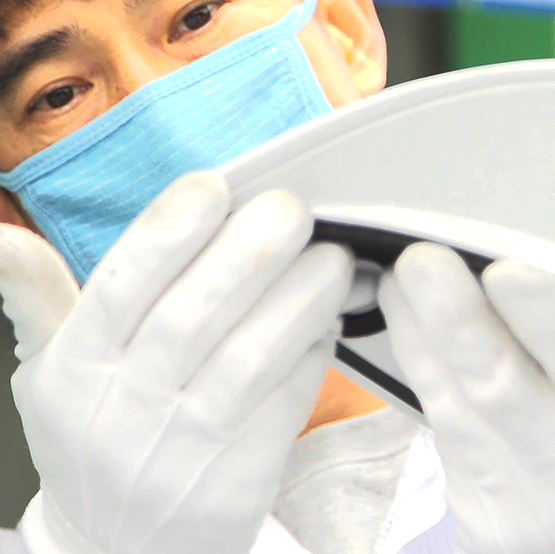

Quality Assurance

Over 25 years experience in supplying OEM Tier 1 and 2 with quality assurance system ISO9001 and TS16949 of our headquarters, we are operating quality assurance system that can supply the best products. MOYA also have sufficient ability and deep experience to perform all environmental tests for PPAP approval level required by customers.

Concept design

Based on our long experience in designing a wide range of blow molding spoilers, MOYA provide the best design to meet customer needs. MOYA provide the best design of products that meets Aero-dynamics elements, various regulations while enhancing the styling of the vehicle.

Engineering Design

Based on concept design, MOYA has more than 25 years of experience in engineering design that can be applied to blow molding by collaboration of design engineer, Tool engineer, molding engineer and production engineer. Starting from mold design, Product design, part design, Check fixture design and applicability of production facilities are reviewed, MOYA do engineering design the product to reflect concept design sufficiently.

Prototyping

Based on the concept design, we build prototype samples by checking our engineering designs before going into tooling and production. By checking the samples in real size before entering the mold, We can verify the match with with the vehicle, assembly problems, compatibility with various processes, packaging and more issues before mass production.

Tool Design

Based on Moya’s 30 years of experience in blow molding engineers, MOYA can make molds optimized for blow molding. A mold is built to produce the optimal blow molding product based on the experience of develop blow molding spoiler for a long time and patents related to blow molding process.

Blow Molding

Blow molding is a technique that produces products with hollow structures. It is a technique to mold a product by blowing half-melted resin, blowing air into a mold. Blow molding can produce a spoiler through a single process. Blow molding has many advantages in strength, design and many parts. By injection molding, need several process to make hollow type of spoiler. Moya can supply World best blow molding products with 25years experience.

Sanding

It is the process of sanding the surface of the blow molded product and making it the optimal condition for painting. MOYA have a long experience and know-how to treat the surface of the product to the best product.

Painting

Moya operates two independent conveyor painting lines, it is the top loading method and the floor loading method. Both painting lines are operated with top OEM quality painting level optimized for each product shape and painting method. With over 20 years of experience, our highly trained engineers are producing the best results with our craftsmanship.

Quality Assurance

Over 25 years experience in supplying OEM Tier 1 and 2 with quality assurance system ISO9001 and TS16949 of our headquarters, we are operating quality assurance system that can supply the best products. MOYA also have sufficient ability and deep experience to perform all environmental tests for PPAP approval level required by customers.